@Finn Berger ang din kommentar om øl dominert av amerikansk humle, så er det øl jeg brygger relativt sjelden, og for meg er en virkelig god, balansert IPA faktisk ganske vanskelig å brygge. Når det gjelder annen, lys, balansert øl, så er det nok sånn at feil blir tydeligere. Men unngår man feil så blir det ofte godt øl, selv uten finkontroll på alle parametre.

Du bruker en utdatert nettleser. Det kan ikke vise dette eller andre nettsteder på riktig måte.

Du bør oppgradere eller bruke en alternativ nettleser.

Du bør oppgradere eller bruke en alternativ nettleser.

Palmer om gjærstartere: Korrigert ny versjon.

- Trådstarter Finn Berger

- Startdato

Jeg brygger etter folkelige metoder og oppsett, og har ikke hatt noen problemer hverken med å lage kjempegode øl, eller å repetere de jeg ønsker. Stresser minst mulig med utregninger og avanserte duppeditter, den investeringen jeg har hatt mest igjen for er vel eget gjæringsrom med noenlunde god temperaturkontroll. Men har selvfølgelig respekt for de som koser seg med å gå dypere inn i teorien.

Imidlertid har det sneket seg inn et lite problem de siste årene, fra da bryggselv skiftet maltleverandør. Har alltid elsket ''de øltypene der ingrediensene ikke har så sterke smaker'', og sørger alltid for å ha særlig en bitter og en brown ale på lager. I det siste blir det alt for mye kjekssmak av bitteren, og brown alen tenderer (svakt, men nok til å irritere grundig) mot sur og metallisk. Dette er et stort savn, jeg simpelthen elsker brown ale med hint av røst og subtil røyksmak.

Merkelig nok er ikke kjøpeølene noe bedre. De siste 3 årene har jeg kun kjøpt 6-7 øl i butikk eller pol, og da spesifikt for å sammenligne med mine egne tilsvarende øl.

Alle variablene på min side er greitt stabile, ingenting er forandret, heller ikke vannkvalitet. Hadde aldri problem tidligere, før dette uheldige skiftet. Bryggselv ser (selvfølgelig, de skal jo selge) ut til å mene at jeg er en smule gal når jeg tar dette opp. Noen andre som har opplevd dette, og funnet en metode for å justere oppskriftene til den nye malten?

Imidlertid har det sneket seg inn et lite problem de siste årene, fra da bryggselv skiftet maltleverandør. Har alltid elsket ''de øltypene der ingrediensene ikke har så sterke smaker'', og sørger alltid for å ha særlig en bitter og en brown ale på lager. I det siste blir det alt for mye kjekssmak av bitteren, og brown alen tenderer (svakt, men nok til å irritere grundig) mot sur og metallisk. Dette er et stort savn, jeg simpelthen elsker brown ale med hint av røst og subtil røyksmak.

Merkelig nok er ikke kjøpeølene noe bedre. De siste 3 årene har jeg kun kjøpt 6-7 øl i butikk eller pol, og da spesifikt for å sammenligne med mine egne tilsvarende øl.

Alle variablene på min side er greitt stabile, ingenting er forandret, heller ikke vannkvalitet. Hadde aldri problem tidligere, før dette uheldige skiftet. Bryggselv ser (selvfølgelig, de skal jo selge) ut til å mene at jeg er en smule gal når jeg tar dette opp. Noen andre som har opplevd dette, og funnet en metode for å justere oppskriftene til den nye malten?

Steinar Huneide

Norbrygg-medlem

Dette har jeg også gjort, og bare unntaksvis har jeg blitt imponert over innkjøpet. Akkurat her tror jeg produktene i utgangspunktet er bedre enn hva vi får til selv, men lider under transport og oppbevaring (lys og varme i butikken) fram til konsumenten får fatt i varen. Vi har jo fordelen med full kontroll helt fra hånd til munn i våre egne brygg.Merkelig nok er ikke kjøpeølene noe bedre. De siste 3 årene har jeg kun kjøpt 6-7 øl i butikk eller pol, og da spesifikt for å sammenligne med mine egne tilsvarende øl.

Helt enig i det, bortsett fra at jeg tror (uten noen vektige bevis) at flertallet av håndverksbryggeriene ikke brygger vesentlig bedre enn en rimelig erfaren hjemmebrygger.

Det med kontroll på variablene etter selve bryggingen bruker jeg som argument for å overbevise ølinterresserte kamerater om å brygge selv.

Det med kontroll på variablene etter selve bryggingen bruker jeg som argument for å overbevise ølinterresserte kamerater om å brygge selv.

Jeg har et ganske pragmatisk forhold til det med å ta kontroll over variasjoner. Jeg tar grep om det jeg opplever som det største problemet til enhver tid. Foreløpig har jeg ikke kommet til timing av starter. Jeg har mer enn nok utfordringer med å holde en noenlunde kontrollert temperatur på hovedgjæringen i sommervarmen...

Finn Berger

Moderator

@msevland

...

Hva kan vi lære av dette? Jeg for min del mener det viser at de tingene vi ikke har kontroll på kan utgjøre forskjeller som totalt overskygger de minste variasjonene vi forsøker å få kontroll på. Det er en grense for når optimalisering slutter å ha noen praktisk verdi.

...

Det er sikkert riktig, og der ligger grunnen til at jeg er dypt skeptisk til å stole så mye på de erfaringene folk - inkludert meg sjøl - rapporterer at de gjør med dette og hint. Men hva slags konklusjon skal vi trekke av det?

Hvis jeg veit hvilken faktor jeg ikke har kontroll på - f.eks. innblanding av oksygen i tappeprosessen - så er det åpenbart ingen vits i å styre med detaljer i relasjon til denne faktoren - som å begrense oksygeninnblanding i mesken. Men hvis jeg bare løst antar at det finnes faktorer jeg ikke har kontroll på - og jeg veit jo at det er en mengde ting som kan påvirke resultatet som jeg ikke styrer - så gir det liten mening å ta hensyn til det. Tror jeg

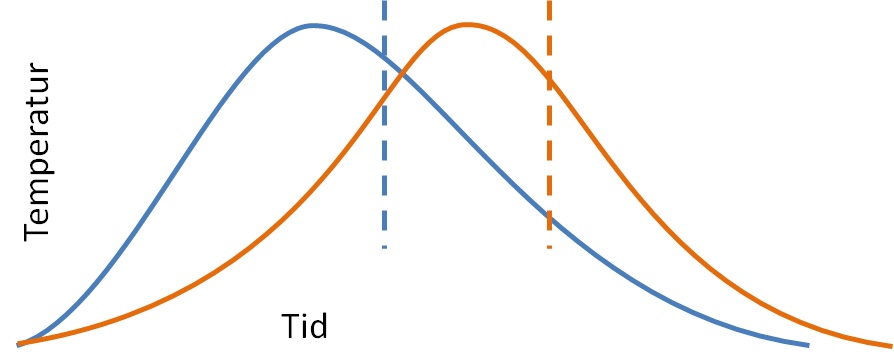

Jeg er ingen tilhenger av mange målinger i en aktiv starter, men tror at temperatur kan være en tilstrekkelig god indikator.

Ved å logge temp vil du kunne se når stormgjæringen er på hell uavhengig av gjærtyper og lagtime. Med litt kontrollmåling er jeg ganske sikker på at man kan finne når kolben skal av røreren

Virker som en god ide. Men det forutsetter vel at du har rører'n stående i et rom med stabil temperatur? (Og at du har muligheten til å logge temperaturen

Temp må være stabilt i rommet, eller i kjøleskapet siden det er tomt i påvente av det kommende brygget. Kjører to sensorer slik at jeg også får inn ambient temp for å kvalitetssikre......Virker som en god ide. Men det forutsetter vel at du har rører'n stående i et rom med stabil temperatur? (Og at du har muligheten til å logge temperaturen)

Den er ikke steril da den inneholder gjær.Jeg er ofte mye enig i hva du skriver, men dette er helt feil. Kveiken (min hvertfall) lager ingen fuselalkoholer, rydder pent opp etter seg, og har konsumeringsklart øl på flaske etter 14 dager. IPAen jeg laget 25. mai står ikke tilbake fra noe annet jeg har brukt Fermentis eller White Labs sine produkter i. Idun tørrgjær blir bare totalt useriøst å dra inn da den hverken er steril eller flokkulerer.

Problemet med å bruke kveiktype gjær er at det smaker kveik. Det er ikke alltid ønskelig, noe som bevitnes av de mikroskopiske antall liter øl som blir brygget med kveikstammer kontra andre kjente stammer.

Det er ikke meningen å slå ned påstandene dine om flott øl, men jeg reagerer på utrykk som «labgjær» og teorien om en konspirasjon blant gjærprodusentene. Det er jo helt bak mål. At noen produsenter gidder å selge oss nisjestrains er jo bare godt nytt.

For det første: Kveik er mange typer gjær. Takket være et lite fremkommelig land, så har kveikkulturene fått utvikle seg helt forskjellig fra sted til sted. De smaker også forskjellig. Det finnes ikke en enkelt kveiksmak.Problemet med å bruke kveiktype gjær er at det smaker kveik. Det er ikke alltid ønskelig, noe som bevitnes av de mikroskopiske antall liter øl som blir brygget med kveikstammer kontra andre kjente stammer.

For det andre: Norsk kveik er en relativt ny oppdagelse innen brygging. Grunnen er at hjemmebrygging av øl i mange år var ulovlig. Kveik er bare i startgropa som kommersiell gjær. Hva det kan bli til kan få spå, men det er ikke egenskapene til kveiksortene som gjør at de foreløpig er lite brukt kommersielt.

For det tredje: Ulike kveiksorter har ulike egenskaper. Det er ikke noe problem. Det er et landskap av nye, spennende muligheter.

Steinar Huneide

Norbrygg-medlem

Der var noen som tok kraftig innover seg å bli sammenlignet med fluefiskere.. big bad corp eller ikke, sammenligningene mine står likevel føler jeg. Noen bønder på vestlandet har laga en supergjær som funker fra 20-40 grader, kan stort underpitches uten negative konsekvenser, kan tørkes, fryses og lagres i årevis. Står seg også i romtemp, hadde et 6 mnd gammelt glass med Lida i boda jeg brukte av, ølet starta å gå etter en halv time og gjæret ut 82% etter tre dager ved 33C. Målte sg på ei flaske jeg tok vare på av den batchen, fire mnd seinere samme gravity. Så må man passe på små detaljer med butikkgjær eller riske å ødelegge batchen.

For det første: Kveik er mange typer gjær. Takket være et lite fremkommelig land, så har kveikkulturene fått utvikle seg helt forskjellig fra sted til sted. De smaker også forskjellig. Det finnes ikke en enkelt kveiksmak.

For det andre: Norsk kveik er en relativt ny oppdagelse innen brygging. Grunnen er at hjemmebrygging av øl i mange år var ulovlig. Kveik er bare i startgropa som kommersiell gjær. Hva det kan bli til kan få spå, men det er ikke egenskapene til kveiksortene som gjør at de foreløpig er lite brukt kommersielt.

For det tredje: Ulike kveiksorter har ulike egenskaper. Det er ikke noe problem. Det er et landskap av nye, spennende muligheter.

For det første: Kveik er mange typer gjær. Takket være et lite fremkommelig land, så har kveikkulturene fått utvikle seg helt forskjellig fra sted til sted. De smaker også forskjellig. Det finnes ikke en enkelt kveiksmak.

For det andre: Norsk kveik er en relativt ny oppdagelse innen brygging. Grunnen er at hjemmebrygging av øl i mange år var ulovlig. Kveik er bare i startgropa som kommersiell gjær. Hva det kan bli til kan få spå, men det er ikke egenskapene til kveiksortene som gjør at de foreløpig er lite brukt kommersielt.

For det tredje: Ulike kveiksorter har ulike egenskaper. Det er ikke noe problem. Det er et landskap av nye, spennende muligheter.

Ja, det er klart at kveik bare er gjær av forskjellige strains. Jeg skrev kveik type gjær. Det er ikke noe problem nei. Om du liker kveik type gjær. Det gjør jeg altså ikke, og mange andre. Jeg syns all øl laget på kveik smaker off og er lite spennende. Og ja det er stort spenn av smaker i de forskjellige kveik (gjær) strainsene.

Kveik er jo ikke noe mer spesielt enn annen gjær. Man kan jo fange gjær i hagen og få greit øl og.

Hvor mange ulike øl brygget på hvor mange ulike kveiker drakk du før du bestemte deg for å ikke like det? Jeg har laget lyse ales, IPA, Amber Ale og mørk amerikansk strong ale i tillegg til tradisjonsøl med einer på samme kveikstamme, og også til en viss grad variert temperaturprofilen. Det eneste jeg kan si er at den egner seg bedre til noen typer enn andre, akkurat på samme måte som annen gjær.Ja, det er klart at kveik bare er gjær av forskjellige strains. Jeg skrev kveik type gjær. Det er ikke noe problem nei. Om du liker kveik type gjær. Det gjør jeg altså ikke, og mange andre. Jeg syns all øl laget på kveik smaker off og er lite spennende. Og ja det er stort spenn av smaker i de forskjellige kveik (gjær) strainsene.

Kveik er jo ikke noe mer spesielt enn annen gjær. Man kan jo fange gjær i hagen og få greit øl og.

Når det gjelder å fange villgjær i hagen, så er det riktig det du sier. Men kveiken er avlet fram gjennom generasjoner. Du skal ha stor flaks for å fange noe lignende i hagen.

Finn Berger

Moderator

Der var noen som tok kraftig innover seg å bli sammenlignet med fluefiskere.. big bad corp eller ikke, sammenligningene mine står likevel føler jeg. Noen bønder på vestlandet har laga en supergjær som funker fra 20-40 grader, kan stort underpitches uten negative konsekvenser, kan tørkes, fryses og lagres i årevis. Står seg også i romtemp, hadde et 6 mnd gammelt glass med Lida i boda jeg brukte av, ølet starta å gå etter en halv time og gjæret ut 82% etter tre dager ved 33C. Målte sg på ei flaske jeg tok vare på av den batchen, fire mnd seinere samme gravity. Så må man passe på små detaljer med butikkgjær eller riske å ødelegge batchen.

Du lager vel en litt kunstig motsetning mellom den "gode" kveiken som er et produkt av prektige bønders brygging gjennom generasjoner, og butikkgjæren, som er laget av "onde" gjærfirmaer som er ute etter pengene våre. Den gjæren som selges av de slemme kapitalistene er da også produkter av en lang bryggetradisjon? Forskjellen er vel bare at i mer siviliserte deler av Europa har øl i lange tider vært en handelsvare, produsert av profesjonelle bryggere, og ikke av bønder. Jeg skjønner ikke helt hvorfor det gir grunnlag for å se ned på de øltypene som er knyttet til de europeiske øtypene.

Det er da forøvrig ikke noen nødvendig motsetning mellom det å ville tjene penger på et produkt og det å ville lage et godt produkt, heller?

Den voldsomme overlevelsesevnen til den norske kveiken er selvfølgelig interessant. Det måtte vel bli sånn, siden man i Norge ikke hadde ressurser til å brygge året rundt; man brygget bare til høytidene, så vidt jeg har forstått - i motsetning til i Danmark, f.eks.. Og da avlet man vel automatisk fram gjær som tålte lange perioder med røff lagring?

Sist redigert:

I'm not sure what Palmer is considering here. Yeast cells initiate carbohydrate storage metabolism, glycogen and trehalose synthesis, due to nutrient limitation, e.g. falling glucose, ammonia and zinc levels. I'm not aware of any evidence that low O2 conditions are a driver here. More a coincidence than an association, I'd suggest. That's not to say what he is suggesting isn't going to work. A good starter can be made without mixing on a stir plate. It just takes more time. A better starter is produced in less time with continuous stirring. The continuous mixing promotes an homogeneous media/environment, where all viable cells have access to nutrients. This is true for up to 72 hours and longer, depending on pitching rate of viable cells. Without mixing, the yeast slurry becomes heterogeneous with some regions having limited nutrient supplies, which promotes stress on otherwise healthy cells. How long to stir? It's important to allow sufficient time for the yeast cells to reach 'quiescence', the resting phase. In this phase, apart from maximum growth being pretty much reached, the cells are packed with storage carbohydrates and they have thickened (less permeable) cell walls making them more tolerant of shock. When pitched into brewing wort, even when the starter is acclimatised to the brewing wort temperature, there is going to be a level of shock response, due to the high sugar concentration of the fresh wort. I recommend stirring until the yeast express clear flocculation behaviour, clumping together during mixing. Then continue stirring for another 24 hours. Then pitch, or store cold for up to a few days before pitching. The stored carbohydrates fuel cell activity during the lag phase, after pitching. Note the stir-plate speed only needs to be set to just keep the yeast in suspension. Quite a low speed is all that's required.

Finn Berger

Moderator

I'm not sure what Palmer is considering here. Yeast cells initiate carbohydrate storage metabolism, glycogen and trehalose synthesis, due to nutrient limitation, e.g. falling glucose, ammonia and zinc levels. I'm not aware of any evidence that low O2 conditions are a driver here. More a coincidence than an association, I'd suggest. That's not to say what he is suggesting isn't going to work. A good starter can be made without mixing on a stir plate. It just takes more time. A better starter is produced in less time with continuous stirring. The continuous mixing promotes an homogeneous media/environment, where all viable cells have access to nutrients. This is true for up to 72 hours and longer, depending on pitching rate of viable cells. Without mixing, the yeast slurry becomes heterogeneous with some regions having limited nutrient supplies, which promotes stress on otherwise healthy cells. How long to stir? It's important to allow sufficient time for the yeast cells to reach 'quiescence', the resting phase. In this phase, apart from maximum growth being pretty much reached, the cells are packed with storage carbohydrates and they have thickened (less permeable) cell walls making them more tolerant of shock. When pitched into brewing wort, even when the starter is acclimatised to the brewing wort temperature, there is going to be a level of shock response, due to the high sugar concentration of the fresh wort. I recommend stirring until the yeast express clear flocculation behaviour, clumping together during mixing. Then continue stirring for another 24 hours. Then pitch, or store cold for up to a few days before pitching. The stored carbohydrates fuel cell activity during the lag phase, after pitching. Note the stir-plate speed only needs to be set to just keep the yeast in suspension. Quite a low speed is all that's required.

The whole point of the stirring can't be to just keep the yeast in suspension? It's also to keep supplying the yeast with oxygen, I think. Surely, that must be the point of intermittently shaking the starter if you do not use a stirplate?

If what Palmer writes about starters in his 2017 edition of How to Brew was wrong, that ought to have sparked some debate by now. Here's what he says:

"The benefit of a stir plate for yeast propagation is that more oxygen is supplied to the yeast for a longer period of time, and this allows for more growth, about 25% more compared to a shaken starter. The wort does not need to be shaken before being placed on the stirplate." (s.122)

He also states that building energy reserves requires "an active period of low oxygen" (s.122) because "Yeast cells rapidly deplete their glycogen reserves when exposed to oxygen." (s.123)

I oxygenate starter wort before pitching yeast, but, yes, initially, stirring promotes wort aeration. As does shaking. After about 30 minutes of high speed stirring, the wort becomes as saturated as it can be, by air. As nutrients get used up, during growth, yeast 'sense' environmental conditions. In spent wort (a nutrient deficient environment), yeast are not programmed to exit quiescence without fresh nutrients being supplied, O2 or not. Fresh glucose in the media is what triggers a shift from dormancy, but the cells (the thickened, protective walls) are not suited to exploit extracellular glucose immediately. They are programmed to metabolise intracellular glycogen, which is easier to metabolise at this stage. During the lag phase, when the cell membranes are replenished, using O2, the cell wall is remodelled, adapting it for glucose uptake. I think Mr Palmer is using 'logic'. I'm guessing no research was referenced to support his reasoning. Nutrient levels are well documented drivers here.

Finn Berger

Moderator

Marius K.

Norbrygg-medlem

Dette kunne jeg sikkert spurt om i tråden for dumme spørsmål, men legger det inn her..

Jeg har normalt sett pakket tuten på Erlenmeyerkolben ganske godt inn med aluminiumsfolie, gjerne to lag for å være sikker på at det ikke skal være et lite hull en plass noe drit kan komme inn. Folien har sittet noenlunde stramt rundt kolben. Ser jo nå at iht denne metoden for å lage starter på, så spinner man i høy hastighet og har folien løst på. Hvor løst har dere folien på? Jeg er 'redd for' at f. eks. en flue e.l. skal kunne finne veien opp under folien og ned i starteren

Jeg er 'redd for' at f. eks. en flue e.l. skal kunne finne veien opp under folien og ned i starteren

Jeg har normalt sett pakket tuten på Erlenmeyerkolben ganske godt inn med aluminiumsfolie, gjerne to lag for å være sikker på at det ikke skal være et lite hull en plass noe drit kan komme inn. Folien har sittet noenlunde stramt rundt kolben. Ser jo nå at iht denne metoden for å lage starter på, så spinner man i høy hastighet og har folien løst på. Hvor løst har dere folien på?

Miguel

Norbrygg-medlem

Løst nok til at jeg selv tror at o2/co2 blir byttet ut. Det jeg pleier å gjøre er å klemme alufolie rundt tuten på EM, så dra hele "formen" opp, og slippe nedpå igjen, da vil den ligge noe løst oppå tuten, men fortsatt ha formen til tuten.Dette kunne jeg sikkert spurt om i tråden for dumme spørsmål, men legger det inn her..

Jeg har normalt sett pakket tuten på Erlenmeyerkolben ganske godt inn med aluminiumsfolie, gjerne to lag for å være sikker på at det ikke skal være et lite hull en plass noe drit kan komme inn. Folien har sittet noenlunde stramt rundt kolben. Ser jo nå at iht denne metoden for å lage starter på, så spinner man i høy hastighet og har folien løst på. Hvor løst har dere folien på?Jeg er 'redd for' at f. eks. en flue e.l. skal kunne finne veien opp under folien og ned i starteren